At Surface, we believe the needs of our customers can co-exist with the needs of our planet. And at Microsoft, we play a key role in the company's goal to be carbon negative, water positive, and zero waste by 20301 — which is why we aim to create devices that reduce carbon impact across their life cycles, are circular by design and are built with integrity.

So as we honor and celebrate Earth Day, here's a snapshot of how we're approaching this challenge.

Low carbon product design

- Thirty percent reduction in total carbon emissions for Surface Laptop Studio compared to its predecessor Surface Book 13."

- All Surface laptop and tablet devices are ENERGY STAR certified, focusing on energy efficiency and battery life. Surface Pro 8 uses 16% less energy than the Surface Pro 7 when tested under the ENERGY STAR Computer Specification 8.0 test method.

- In our supply chain, in 2021, we finished a complete conversion of our primary distribution center in Europe to 100% renewable energy. This facility now generates 1.3 million kWh (kilowatt-hours) from solar energy and avoids 690 mtCO2e (metric tons of carbon dioxide equivalent) annually.

- Our premium type cover is wrapped in Alcantara® material which has been Certified Carbon Neutral since 2009. Alcantara gives Surface Type Covers texture and a durable finish for easy cleaning and care.

Circular by design

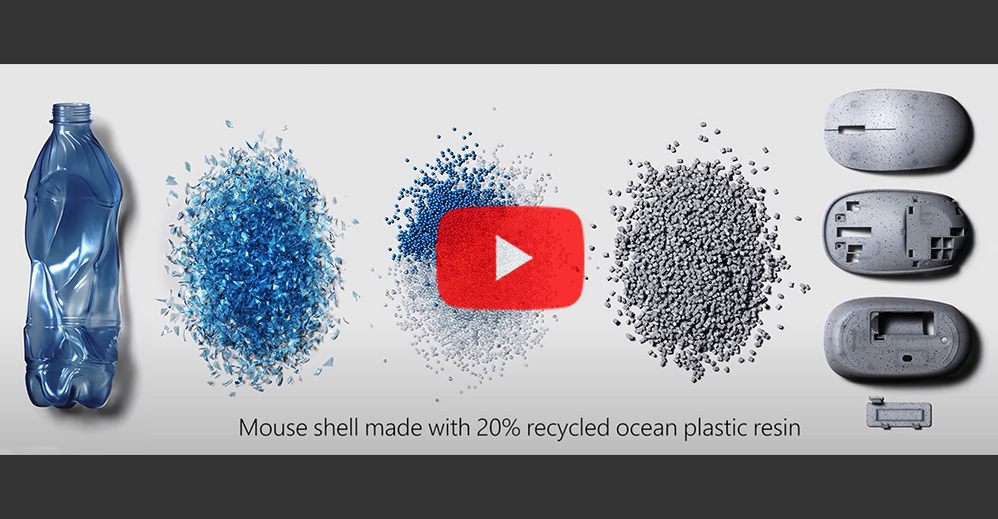

- Innovating with new recycled materials: In October 2021, we launched the Ocean Plastic Mouse, which has a shell made with 20% recycled ocean plastic, the first consumer electronics application of this material. Going beyond ocean-bound plastic (plastic collected within 50 km of shorelines), each mouse contains recycled resin derived from recycled water bottles taken directly out of oceans, beaches, and waterways.

- See this video to learn more:

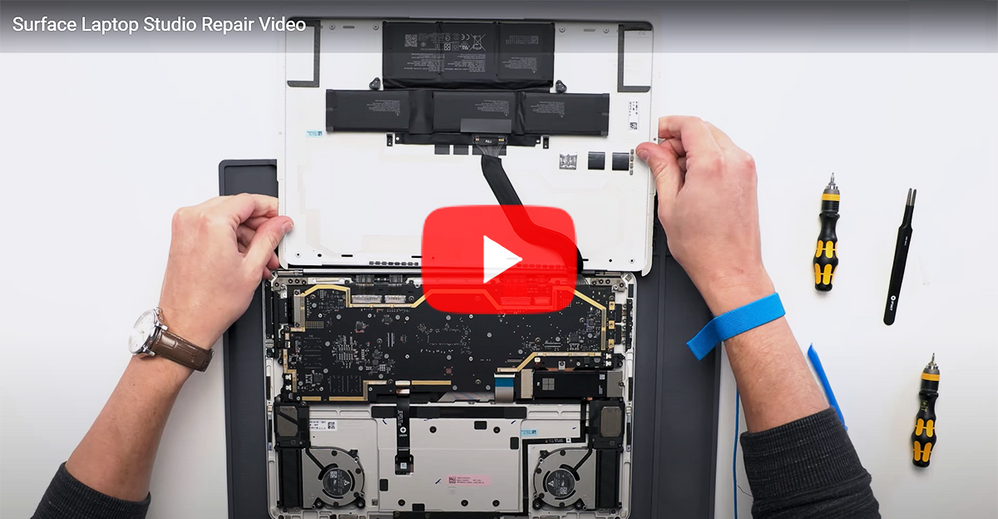

- Repairability and serviceability can extend the lifespan of our devices: In 2021, our Design for Repair engineering program helped launch the Surface Pro 8, the Surface Laptop Studio, and Surface Laptop SE, which are some of the most repairable devices in their product lines with replaceable displays, batteries, keyboards, and more.

- Check out this video showing the repairability features of Surface Laptop Studio:

- The commercial packaging design meets customer requests for the highest density packaging for large-scale deployment. The packaging system meets the most stringent EPEAT requirements for packaging density.

Integrity built-in

The integrity we build into our products is why we share them with the world. Our design process focuses on creating the highest quality products with a responsible supply chain that meets higher ethical and environmental standards.

- Reimagining product lifecycle through the lens of sustainability.

- EPEAT Gold: Microsoft Surface has achieved the highest possible rating, EPEAT Gold2, for all of our newest generation laptops and tablets in 30 countries, including the US and Canada.

- Life cycle assessments: We adhere to a product environmental LCA methodology that calculates the environmental impacts of all activities associated with the product lifecycle.

- Surface emissions estimator: Helps commercial customers estimate emissions3 associated with a Surface device or accessories based on use and locations.

- Responsibly made: We hold suppliers accountable to Social and Environmental Accountability (SEA) standards and invest in building their SEA capabilities.

The road ahead

Advances in material science are opening up new avenues for Surface to explore. Here are some examples:

- Labs: In our labs, we're assessing the use of a "lower-carbon and reduced-waste flax-based wiring board" and experimenting with 3D printing. We're investigating the feasibility of relying on 100% post-industrial recycled tin in our soldering paste. We aim to reduce overall materials through new spacing guidelines that could shrink our circuit boards by as much as 25%.

- Manufacturing: We aim to reuse manufacturing scrap in aluminum production, such as the use of lower-carbon, 100% post-industrial recycled closed-loop aluminum for future Surface computer housings.

- Post-industrial scrap: For neodymium in magnets, we are also exploring the use of post-industrial scrap as a manufacturing feedstock. This will enable us to produce 100% recycled neodymium in magnets for future products -- versus reliance on this rare earth material.

- Reduced reliance on virgin raw materials: We're using more recycled materials in Surface packaging and devices. Twenty percent of the materials in our Surface dock, for instance, come from post-consumer recycled (PCR) plastic, and 25% of the thermal module for Surface Laptop Studio is made from PCR plastic.

- Planet and device friendly packaging: As this graphic shows, we're aiming to reduce single use plastics with an eye to building 100% recyclable surface devices by 2030.

We know this is only a small step on our journey to build a more sustainable future.

References

1. 2021 Environmental Sustainability Report | Microsoft CSR

2. EPEAT rating availability may differ by market.

3. Contact your Microsoft representative for more information.

Posted at https://sl.advdat.com/3vB69rkhttps://sl.advdat.com/3vB69rk