Since 2009 I have been at the forefront of creating value from industrial IoT (IIoT). I have seen first-hand that using asset data to do remote monitoring, predictive maintenance, and energy management across thousands of devices creates significant value and sustainability potential – but the process to go from idea to scaled implementation requires the consistent collection of unified data from industrial assets. This is easier said than done across the multitude of manufacturers, device types, and implementations you find on a typical company site. To manage this, you need a software layer that can remove complexity and allow you to focus on reaping the benefits for your business.

That is why we have built Omnio Edge: the unified data layer for industrial IoT. Organizations around the world are already using Omnio Edge to connect anything from sensors to more complex devices and all the way to PLCs, CNC machines, and OPC UA servers in a few minutes. Thanks to the unique unification layer, the data delivered from the different assets are always unified to a common model. This allows the data to flow effortlessly into algorithms, applications, and platforms such as Azure IoT Central - while you can focus on getting value from the data.

About Omnio

Founded in 2017 and headquartered in Copenhagen, Omnio enables organizations such as ABB, IBM, and RS Components to connect assets and generate value for themselves and their customers. Thanks to our long Industry background, we understand the use-cases and the challenges you face and we build software to solve them best possible.

Unified data is the key to success

Whether you are connecting sensors, devices, PLCs, CNCs, or even OPC UA servers, the unification and data quality is paramount to success. Omnio Edge is built for both green and brownfield locations – and handles everything from making it easy to see which data is available in your assets, extracting it, transforming it into a unified data model, and delivering it to where you need it. Together with Microsoft, we have built the simplest way to securely connect all your assets, generate the digital twin device model, and ship data to Azure IoT Edge, IoT Hub, or IoT Central.

Using Omnio Edge you can instantly connect any of the 75.000 supported models of Modbus, Ethernet/IP and Profinet devices such as power meters, sensors, drives and many more. You can also connect any BACnet device with the built-in data discovery capability, as well as Siemens S7 PLCs, Allen-Bradley PLCs, CNC machines through MTConnect and of course OPC UA servers you may already have on the location. All data will be extracted and unified at the edge, and delivered straight to where you need it – unified and ready for use.

Ease of use unleashes the potential

Let us take an example – connecting a couple of devices to Azure IoT Central, using Omnio Edge. In this case, we will connect a Modbus power meter from IME and a VFD from Schneider Electric.

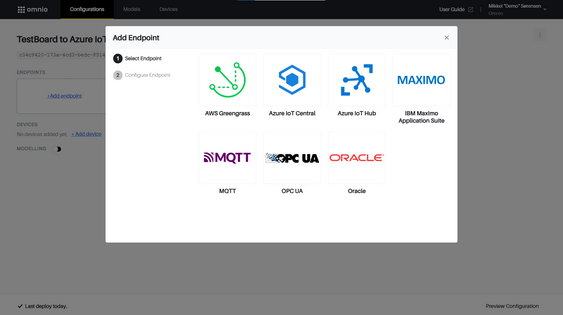

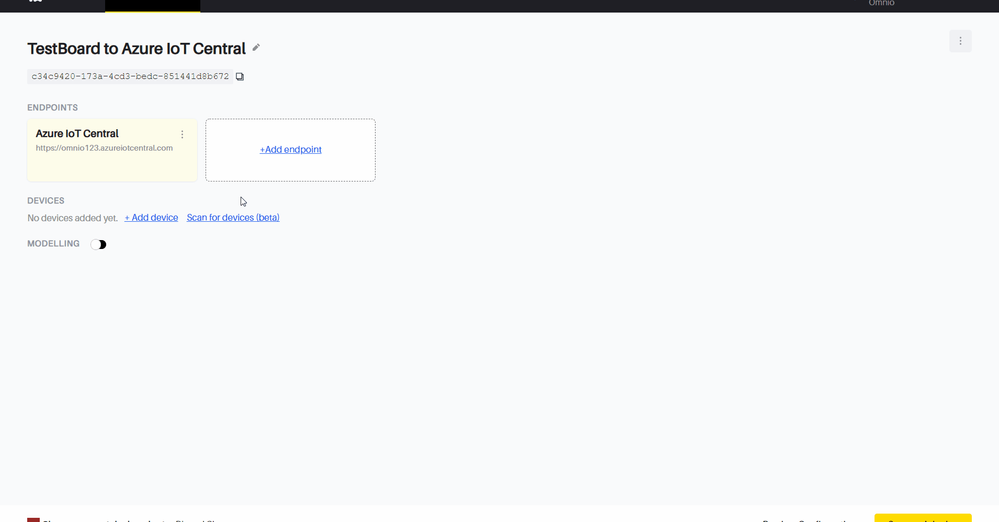

First, we create a new configuration in the Omnio Config tool. We add an Azure IoT Central endpoint using the URL of the IoT Central instance and the API key generated in the IoT Central.

Next, we add the devices either through scanning the network or adding the details manually if network security does not allow for scanning. Adding devices manually means choosing the device from the library and adding the IP of the device.

Last, we pick the data we want from the devices. Note how the Omnio logo signifies a variable that we have standardized – ensuring that naming, units of measurement and data structure is standardized. Behind the scenes, Omnio Edge fetches all the data and performs any additional calculations needed to deliver the data correctly.

And that is it! Once we click Save and deploy, Omnio will automatically create the two devices, including the DTDL Device Model via IoT Central APIs. Omnio Edge will connect and provision the devices with DPS and data will start flowing.

The device template is fully populated with unified names and semantics – enabling you to quickly build a dashboard such as this:

In this dashboard, you can now track the power consumption and other parameters you can use for optimizing energy and ensuring uptime of the equipment.

Scaling from 1 to 100, to 1000 and beyond

Connecting your first devices is only the beginning – but the ease and unification stay with you to enable the scalability of your solution. Once you have built an application, which you want to use at scale, connecting more assets to it is simple. If you have connected 1 power meter you will likely connect more and with the unification layer in Omnio Edge you can be sure the data will always be unified to the same model and slot directly into your application – and the same is the case for your other devices, sensors, PLCs and whatever else you want to connect.

Bottomline

Building value-adding IoT applications requires the capability to easily connect unified device data, iterate until you are satisfied – and then connect many more assets to the application. This is only possible with a solution that ensures ease-of-use and unified data across your devices. With Omnio Edge you can get started quickly and scale effortlessly, enabling you to unleash the potential of the data in your assets.

Posted at https://sl.advdat.com/3L6n8HFhttps://sl.advdat.com/3L6n8HF